A volute is a term to describe the part of a handrail which is curved in plan and elevation views. Volutes are used to start a rail system (handrail) and are an element for the bullnose step.

Basic Setting Out

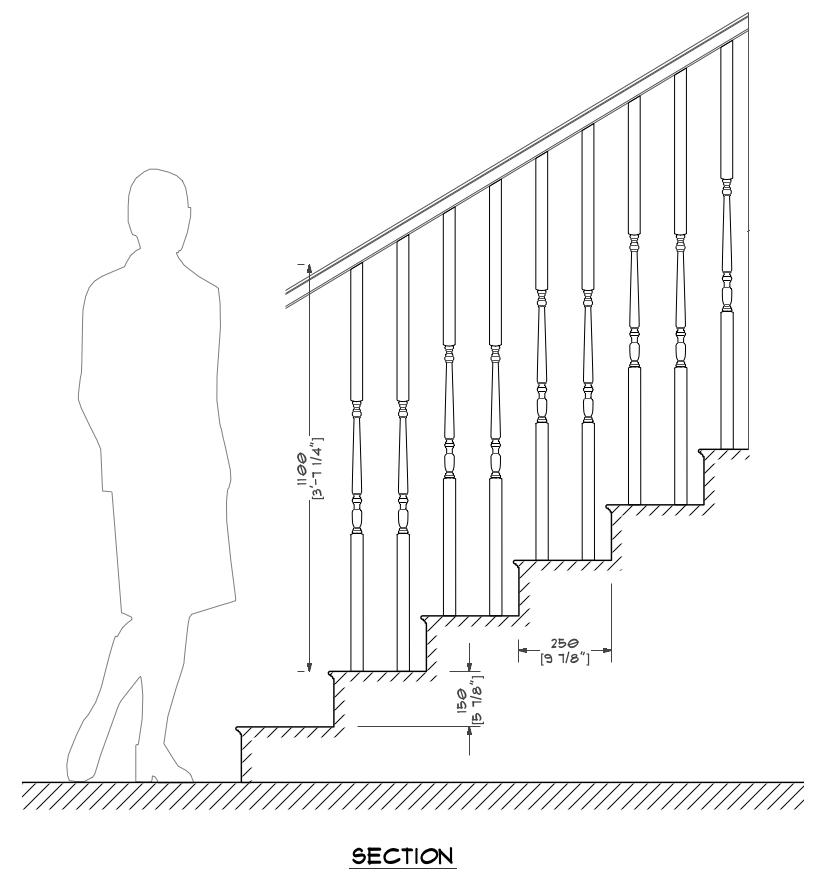

Before we start laying out the volute, some basic geometry and parameter should be set out first. The going and rise of the stair treads, handrail height, width of the handrail profile and how wide is the volute (make sure there is enough room!).

For example:

Tread going: 250mm

Tread rise: 150mm

Handrail height: 1100mm

Handrail profile width: 68mm (James Mansfield M62)

Width of volute: 11″

Note: if you are using a wider handrail profile, the overall width of the volute may also need to increase in order to give it enough space for it to spiral.

Setting out volute

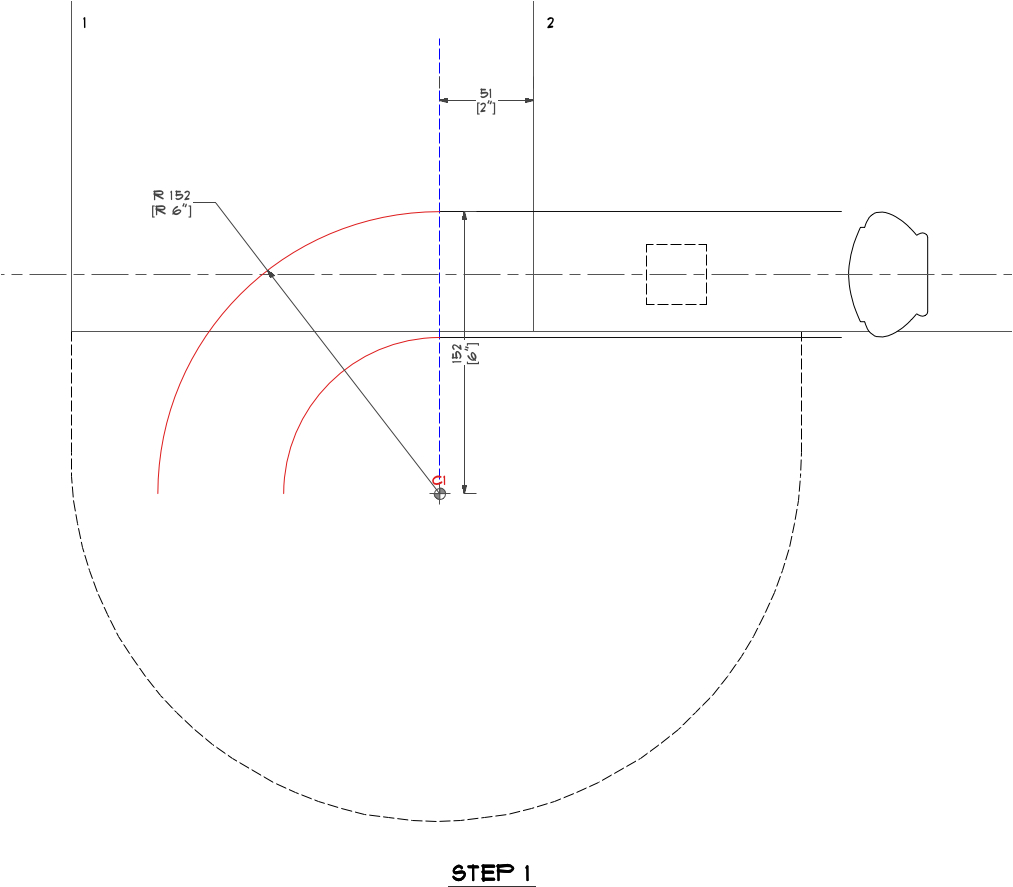

With the basic geometry set out, we can now start setting out the volute. Here is one of those geometry that actually work best in imperial system rather than metric.

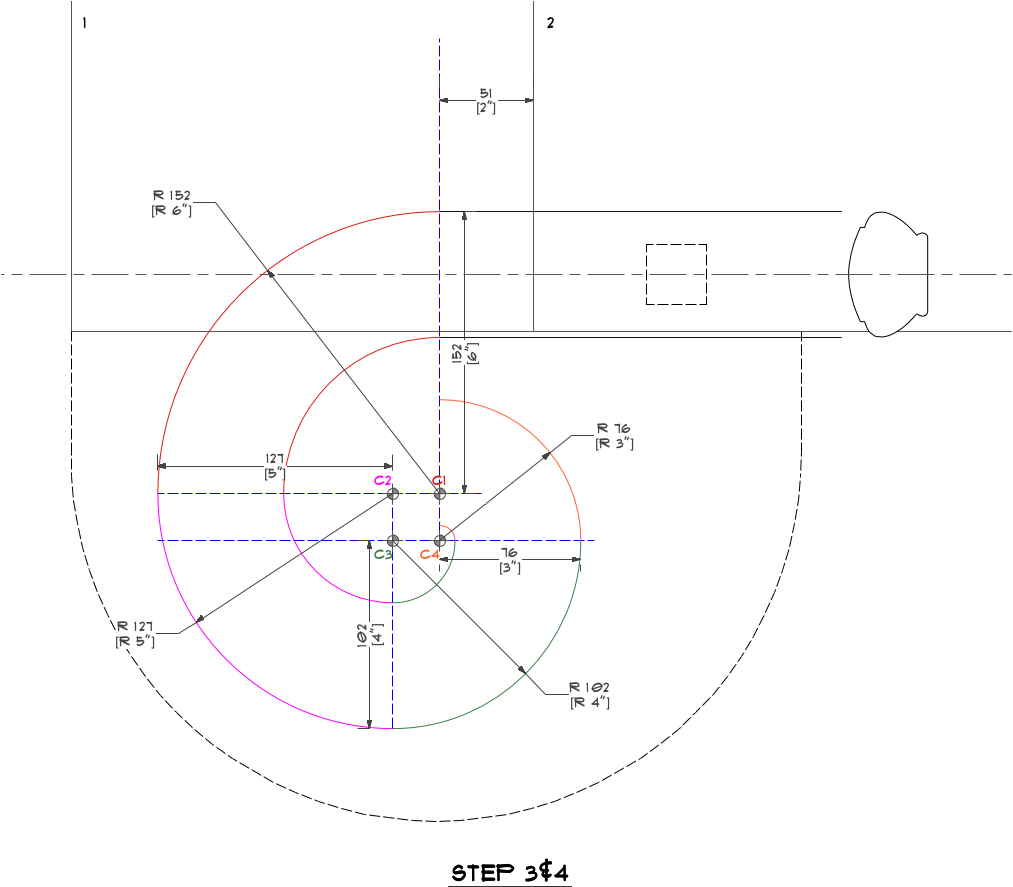

The radius of a the spiral reduces every quarter turn of the volute by 1″. Therefore with an 11″ overall width, the first radius will be 6″, the second radius will be 5″ (6″ + 5″ = 11″). And the start of the spiral can be set 2″ in front of the second tread.

From the outside line of the volute (inside face of the handrail), mark 2″ in front of the second tread, and 6″ away. This will be the centre point (C1) of the first arc. Using centre point C1 we draw a 90degree turn arc. And we can also offset the arc by the width of the handrail (68mm).

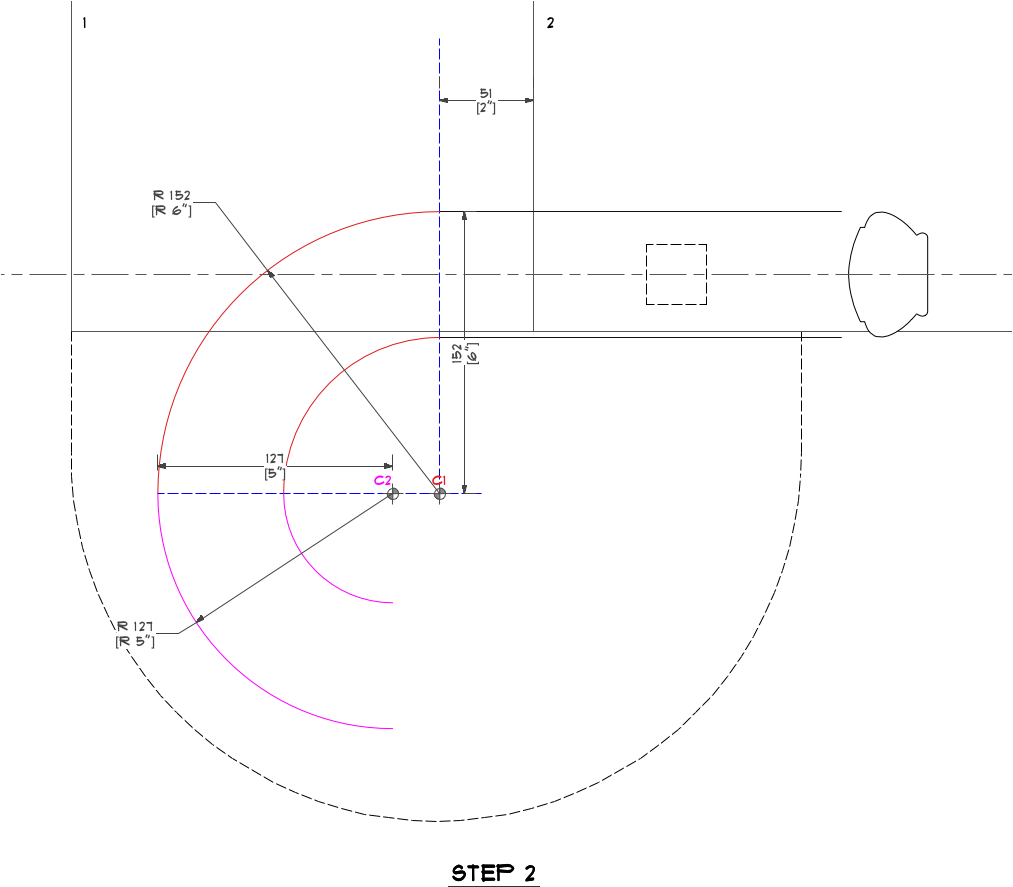

The radius of the second arc is reduced by 1″. Therefore from the end of the first arc, we will draw another 90degree arc with a radius of 5″ from centre point C2.

And we will repeat the steps 2 more time, reducing the radius by 1″ each 90degree turn.

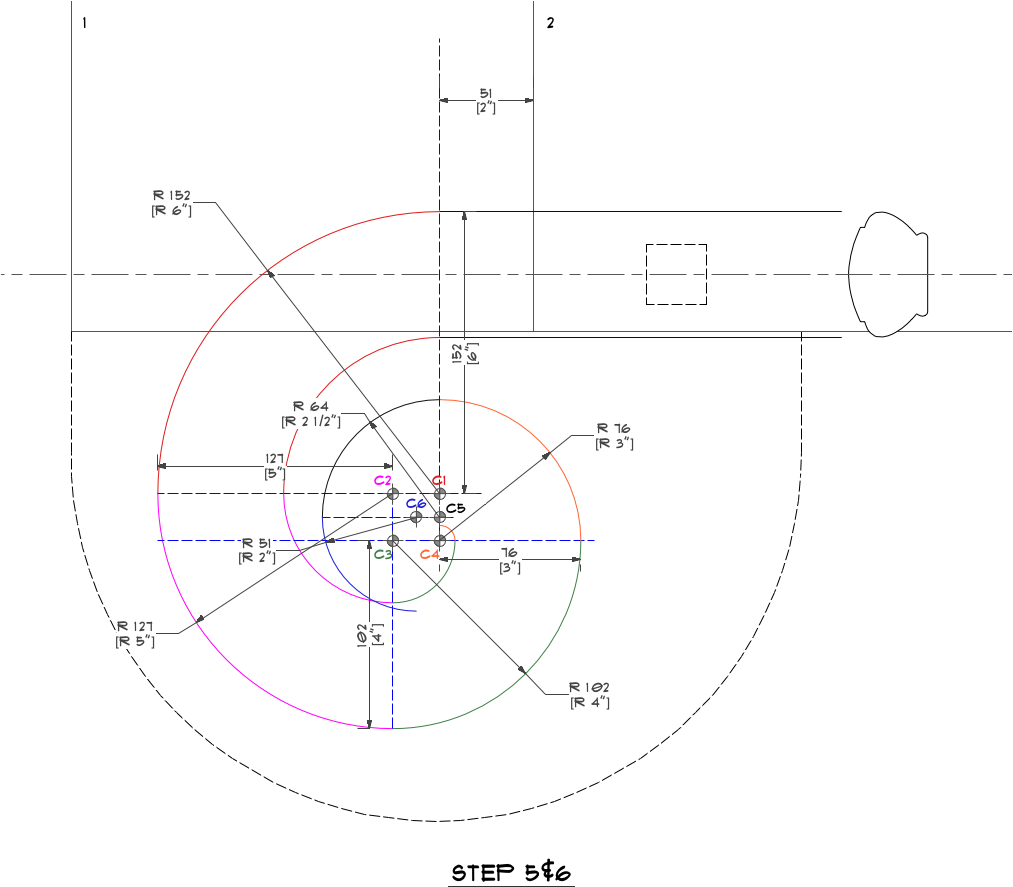

At turn 5, if we reducing the radius by 1″ as we have been doing, we will be starting at the same centre point as turn 1 at point C1. That will result turn 5 being parallel to turn 1, therefore for turn 5 & 6 we will reduce the radius by 1/2″ at each turn instead.

The last arc turn 6 has a centre point C6 which is in the centre of C1-C4. This will become the centre point of the eye of the volute. Therefore we can continue the turn 6 (which has a radius of 2″) and turn it into a circle, as well as start cleaning up the drawing.

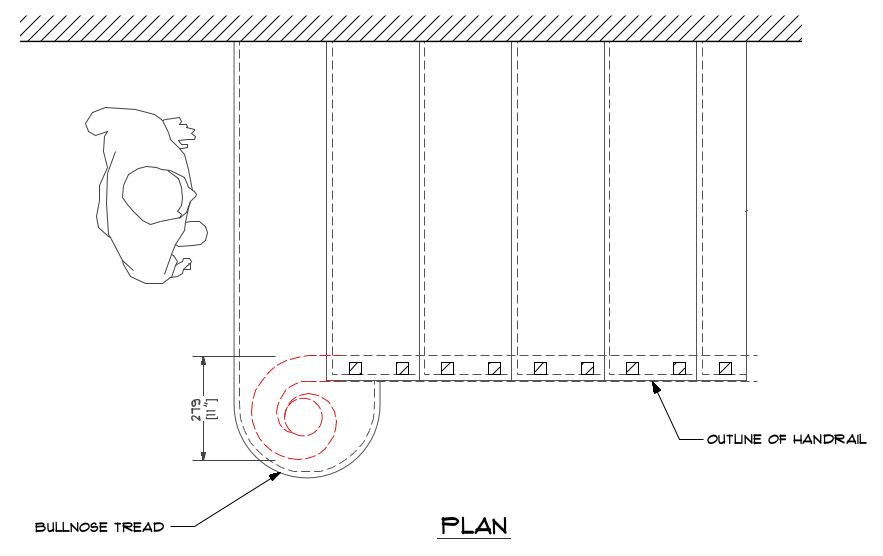

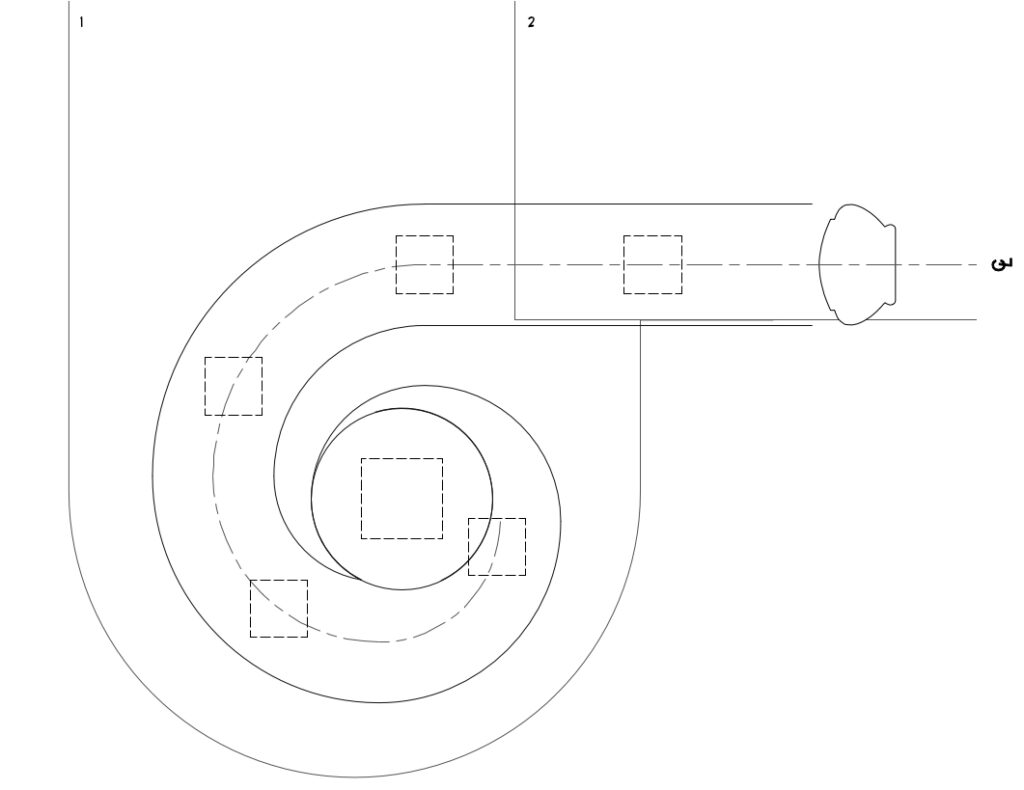

After cleaning up the drawing, we can place the spindles along the volute as well. Set them out in the same spacing along the centre line. In this case they are 5″ apart, and finish off at the centre of the eye with a newel post or a spindle.

For the bullnose tread, give roughly equal spacing front and back so that the volute sits nicely centre.

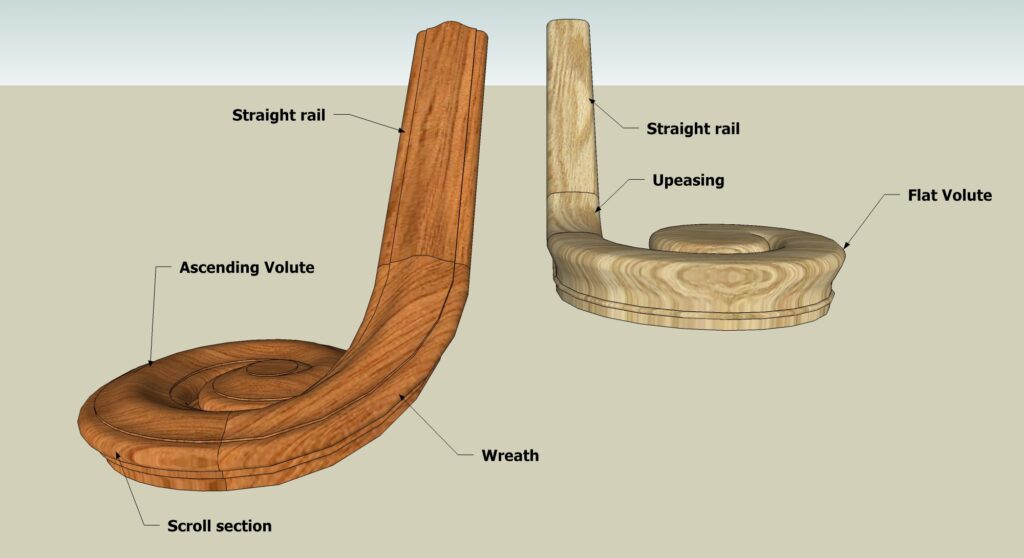

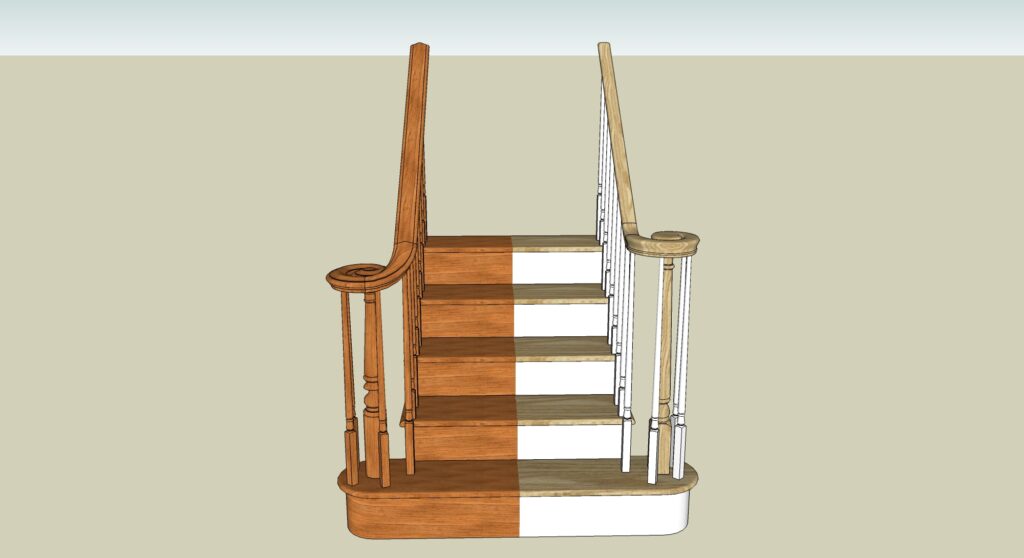

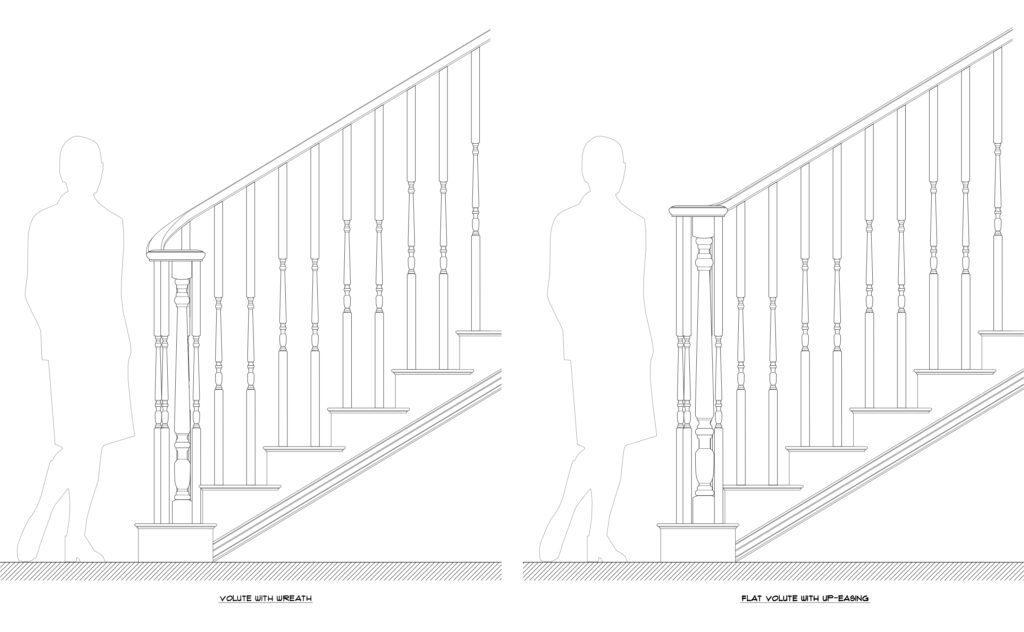

Volute with an up-easing or wreath

There are two type of volute available. Traditionally these are hand crafted with a wreath, where the first turn of the volute, which transitions from raked to level as it turns through the first 90 degrees. Or a more commercially produced flat volute with an up-easing, where the spiral part of the volute is completely flat and it ramp up at the straight run of the handrail.

Due to the nature of the manufacturing of a flat volute (its easier to mass produce and CNC machine), which resulting the flat volute required to be set at a high height at the first step, a longer spindles and newel post is also required to accommodate its height. A person starting up such a stair must raise their hand uncomfortably high !

Depends on time / budget / resources available, which may indicate which style of volute would you choose. A flat volute is can be easily source from most companies that sells staircase components, downside is profile choices are often limited (beside the height it needs to be set at). Some companies does sells a volute with wreath, often with a long lead time and most certainly at a higher cost.

Occasionally a bendy handrail mould are available they are a great alternative, but they might not provide enough structural rigidity. Alternatively, if you have plasterer as part of your construction crew they may also be able to cast one in a form of rigid plastic (fast-cast) or similar.

Be sure to discuss with your construction manager beforehand and make sure they are able to achieve the look while providing sufficient safety for everyone on set.